Hosefloats 130

Hosefloats, an industry standard for the floatation of hoses, conduit and cables for dredging, mining and marine applications.

An easy to install solution that allows pipes to bend and flex, while maintaining low resistance to waves, wind and current.

Product Information

| PIPEFLOAT SPACING GUIDE | Water : 4 sets for every 12 meters of pipe Slurry : 7 sets for every 12 meters of pipe eg. 100m Waterpipe: (100m / 12m) x 4 = 33 Floats recommended for half submergence |

PACKING GUIDE

| PALLET LOAD | 1.2m x 1.2m x 2.25m (height) 59 Sets per pallet Approx Weight 405Kg |

*RESERVE BUOYANCY is the weight the float will carry before full submergence.

*O/D is the Outside Diameter.

*Dimensions and weights are nominal.

INCLUSIONS

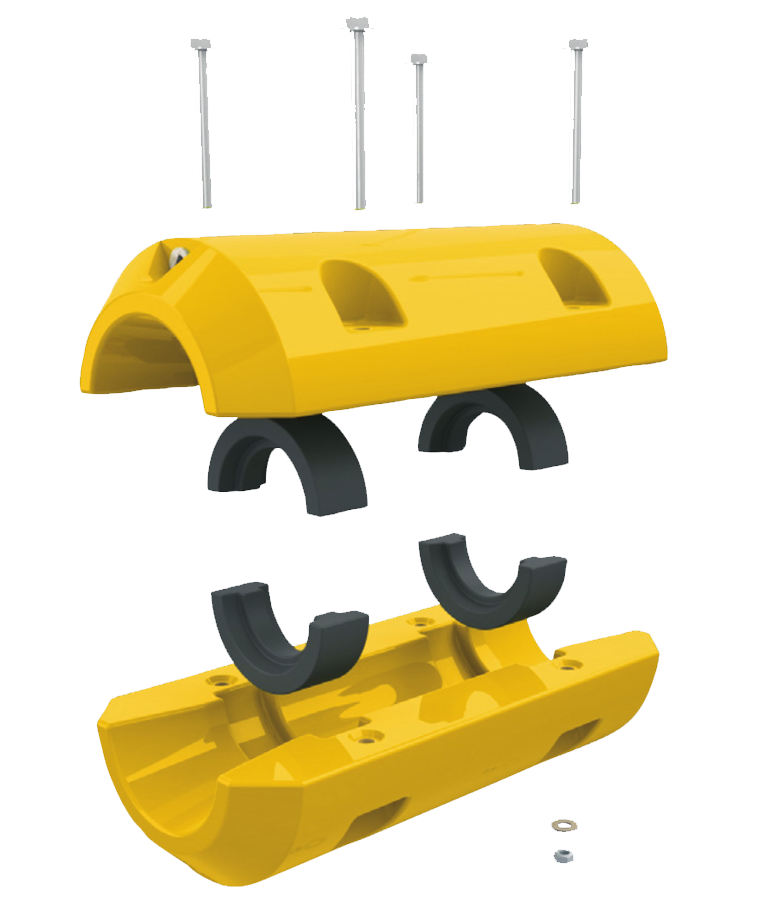

A hosefloat set comprises:

- 2 pipefloats halves

- 2 variable rubber bushes

- A galvanised assembly kit which includes:

- 4 Rods

- 8 Nuts

- 8 Washers

SPECIFICATIONS

- Manufactured from polyethylene.

- Standard colour is yellow or red.

- Stainless steel inserts used in crush areas.

- Rubber Bushes are manufactured from EPDM which is totally resistant to harsh environment.

- All floats are pressure tested prior to dispatch.

- Recyclable and VOC Free.

- Australian made and designed.

- Specifications are subject to change without notice.

STAINLESS STEEL KITS

Marine Grade, SAE 316 stainless steel assembly kits for

corrosive environments are available at an additional cost.

- Kit includes: 4 Rods, 8 Nuts and 8 Washers.

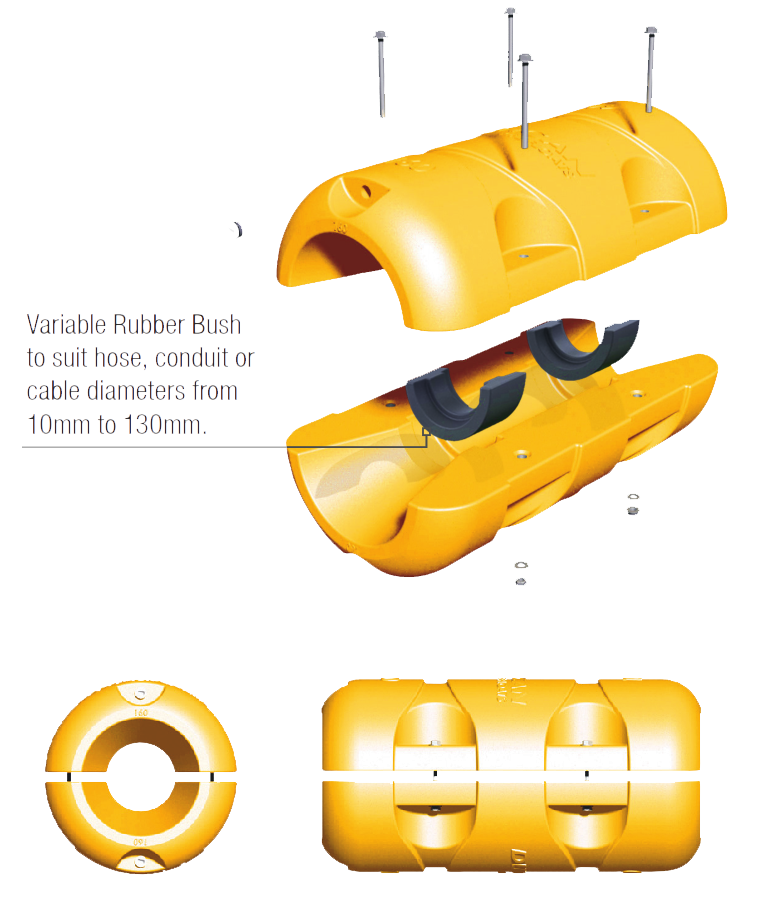

Hosefloats Bushes

Preparation of a Hosefloat Bush is

simple 2 step process:

Firmly secure the bush to a drill press

1.) Using a hole-saw kit, drill a hole to the pipe diameter first

2.) Using a saw cut the bushes in half using the cut grooves

For safety, use a:

1. Drill press

2. Band saw

EPDM Rubber Bushes

Hosefloats bushes are made from EPDM rubber, a type of synthetic rubber. It’s main properties are heat, ozone and weather resistance. It is also resistant to polar substances and steam, with excellent electrical insulating properties and resistance to ordinary diluted acids and alkalines.

Final Assembly